On Sunday I disassembled this 1936 Snap On ratchet, cleaned it, put fresh grease inside and put it back together.

Just after I started I thought about something that people may take for granted.

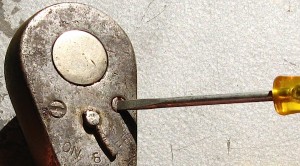

Notice the two screws holding it together. The slot in one is plainly seen and the other is filled with oil and dirt.

I knew better than to think that the screwdriver would displace that crud and seat properly. It wouldn’t. Instead of trying I took an extra minute and a machinists scriber and cleaned the crud out.

This is one of the rare instances where its okay to use a tool for something it wasnt made for. Machinists scribers are for scribing, not digging crud out of screw slots but doing so wont hurt it and it works great for the job.

Its also important to use the proper size screwdriver.

In the first picture below you can see that the screwdriver would fit but there will be plenty of extra room. This would cause the screwdriver to leave depressions on either side of the screw slot and cam out as its turned. The second pic is a proper sized screwdriver.

Here’s a machine screw that was deliberately driven with the wrong size screwdriver. Now that its damaged , re-use would be difficult even with the proper size driver.

January 2nd, 2009 - 7:07 pm

hi glenn! this is jean, I saw you at the coffee exchange today… I really like this tool blog, it is great to see the photos of before-and-after, and I learned a couple of things, too! thanks for writing, I am psyched to see what shows up on here next…

December 16th, 2009 - 3:09 pm

jeez Glenn, you’re the earl proulx of your generation!